By Stephanie Meredith

May 6, 2020

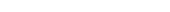

The U.S. Mint produces billions of coins a year, some that you use in daily commerce and some just for collecting. If you’ve ever been on a tour of the Philadelphia or Denver Mint facilities, you learned how coins are made. But what happens before the coin production process begins?

A coin or medal starts with legislation. Congress passes laws to authorize the Mint to make coins and medals with certain designs and purposes. One recent piece of legislation is the President George H.W. Bush and First Spouse Barbara Bush Coin Act. It allows the Mint to make George H.W. Bush Presidential $1 Coins and Barbara Bush First Spouse Gold Coins.

Although Congress passes laws for different coins and medals, law also allows the Secretary of the Treasury to authorize them. The Secretary has the authority to tell the Mint to make certain gold coins and silver and bronze medals as numismatic products.

Once legislation is signed, the Mint starts the design process. The law sometimes includes design and inscription requirements. The Mint also connects with the stakeholder named by Congress to discuss any requirements they have. The Mint then produces a design brief to guide the artists and holds a kickoff call, connecting the subject matter experts with the artists.

Design Process

The artists research the subject and submit design drawings to the Mint. U.S. Mint medallic artists always have the opportunity to submit designs. Artist Infusion Program (AIP) artists also create designs, but they participate by invitation from the Mint.

Sometimes legislation calls for a public design competition to choose a design submitted by a member of the public. A public design competition decided the designs of the World War I Centennial Silver Dollar Coin.

“The Office of Design Management is committed to the principle of artistic excellence,” says Design Manager Megan Sullivan. “As we manage each project, we are neutral stewards of the process, really working to ensure that the artist’s vision is prioritized.”

After the artists submit their design ideas, the Mint reviews them. A legal review looks at whether the designs meet requirements in the law, follow copyright laws, and use correct symbols. The Mint’s chief engraver provides feedback for artistic improvements. A coinability check looks for anything that wouldn’t strike well, such as letters that are too small or too close together. All of this feedback goes back to the artists so they can revise their designs.

Once the designs go through a couple rounds of internal revisions, the stakeholders review and provide feedback. They look for accuracy and appropriateness of the designs. The artists incorporate the feedback and come back with additional revisions until both the stakeholders and the Mint consider the design portfolio ready for committees to review.

Watch the video below to see what inspired the artists of the World War I Silver Dollar Coin.

Design Selection

The Citizens Coinage Advisory Committee (CCAC) and the U.S. Commission of Fine Arts (CFA) hold meetings to review the design portfolio. The stakeholders or other experts may share their thoughts on the portfolio at these meetings. The CCAC and CFA each recommend a design to the Secretary of the Treasury. After considering these recommendations, the Secretary chooses the final design.

The approved design is still in the form of line art. A Mint medallic artist needs to sculpt the design, in clay or digitally.

The finished sculpt is carved into a master hub which makes the dies used to produce the coin or medal. But before the Mint starts making the new coin or medal in bulk, the manufacturing department does a test strike. The test strike shows if there is any part of the design that doesn’t strike well. If everything looks good, the production process begins.

“As exciting as the design process is, nothing beats the moment when you finally see the finished coin. The artwork takes on a whole new dimension when you can turn it in your hand, see it shimmer in the light,” says Design Manager Roger Vasquez.

You can learn about the how coins are made in part two of this series, Coin Production Terminology. Or tour the Philadelphia or Denver Mint locations to see the process in person.

How Coins Are Made Series

- Part Two: Coin Production Terminology

- Part Three: Bringing Coins Into Circulation

See more Inside the Mint articles.